Inertia bases are crucial components in construction and industrial settings, especially when dealing with heavy machinery and equipment that generates significant vibrations. They provide a stable platform, reducing the transfer of vibrations to the building structure, which can lead to increased equipment lifespan and improved safety. Understanding the best materials to use for building inertia bases is essential for ensuring optimal performance and durability. Here’s an in-depth look at the top materials used and why they are preferred.

Understanding Inertia Bases

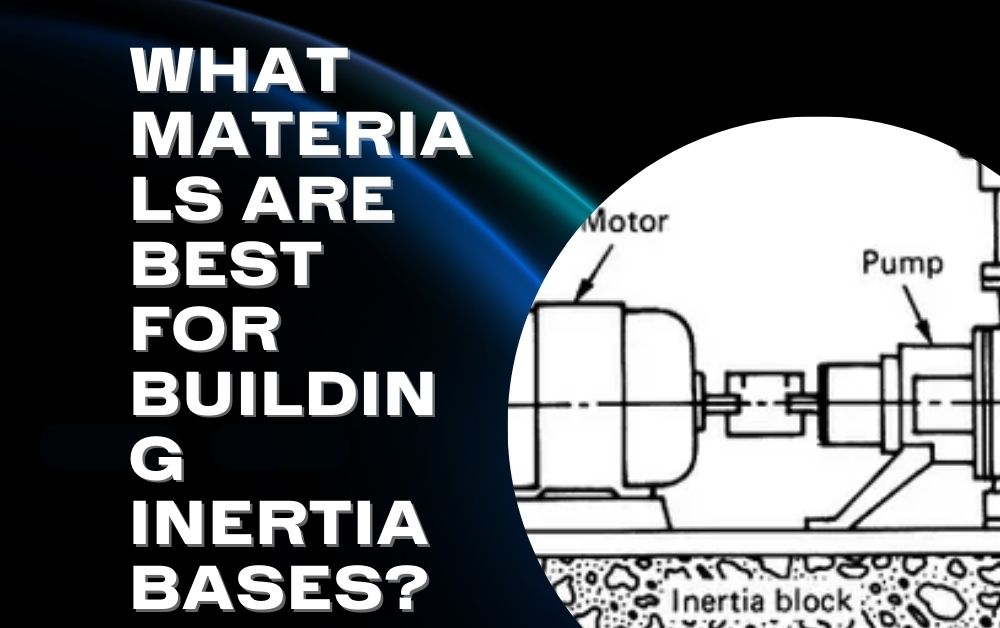

Before diving into the materials, it’s important to understand what inertia bases are and their role. Inertia bases are designed to support mechanical equipment, absorb vibrations, and provide a stable and secure foundation. They typically consist of a concrete mass that’s reinforced with steel, resting on vibration isolators to minimize the transmission of vibrations to the surrounding structure.

Key Functions of Inertia Bases

The primary function of an inertia base is to stabilize heavy machinery, such as HVAC units, generators, and pumps, by increasing the system’s mass. This addition of mass helps in damping vibrations and reduces movement caused by operational forces. By doing so, inertia bases not only protect the building’s structure but also enhance the efficiency and extend the life of the machinery they support.

Note – Looking to enhance the stability and efficiency of your heavy machinery? Explore our top-quality Inertia Bases designed for optimal vibration control and support. Don’t compromise on the foundation of your equipment’s performance. Contact us today to find the perfect inertia base solution tailored to your needs!

Preferred Materials for Inertia Bases

Choosing the right materials for constructing an inertia base is vital for achieving the desired vibration control and stability. Here are some of the most commonly used materials:

Concrete

Concrete is the most popular choice for inertia bases due to its high density and ability to be molded into various shapes and sizes. It is particularly effective in absorbing and dampening vibrations. When designing an inertia base, the concrete is typically poured around a steel reinforcement frame, which provides additional strength and ensures the longevity of the base.

Steel

Steel is often used in conjunction with concrete as a reinforcement. It provides the necessary tensile strength that concrete lacks, making the inertia base much more durable and resistant to cracking under stress. Steel rebar or mesh is embedded within the concrete to form a composite material that effectively carries the load and withstands operational vibrations.

Factors to Consider When Choosing Materials

When selecting materials for an inertia base, several factors need to be considered to ensure effectiveness and durability:

Density

The density of the material is crucial because higher density materials are better at absorbing and reducing vibrations. Concrete, with its significant mass, is ideal for this purpose, as it helps to dampen the vibrations more effectively than lighter materials.

Durability

The material’s durability is also a key consideration. It should withstand the constant stress and vibrations without degrading or losing structural integrity over time. Reinforced concrete offers excellent durability, which is why it is a preferred choice in many industrial applications.

Cost-effectiveness

Cost is always a factor in construction projects. Materials chosen should not only be effective but also cost-efficient. Concrete and steel are both cost-effective options, particularly when considering their long-term benefits in terms of reduced maintenance and repair costs.

Conclusion

The choice of materials for building inertia bases is critical in ensuring that they perform their intended function effectively. Concrete, especially when reinforced with steel, provides the necessary mass and strength to support heavy equipment and absorb vibrations. This combination not only protects the structural integrity of buildings but also ensures that machinery operates efficiently and with minimal disturbance. By selecting the right materials and considering factors like density, durability, and cost, you can effectively enhance the performance and longevity of both the equipment and the building itself.

For more insightful articles related to this topic, feel free to visit guestpostreview.com